Transforming Refueling Operations: From Manual to Automated Data Capture & Reporting

- Mindshift Analytics

- Aug 3, 2024

- 2 min read

Updated: Aug 5, 2024

Most sites still struggle with pen-and-paper data capture, back-end data entry in computers, and consolidation on Excel sheets. Data loggers travel with the bowser, making manual entries of refueling and HMR/odometer readings. This data is then manually posted into computers, resulting in avoidable costs, delays, manipulation, and posting errors. The lack of accurate, granular, and timely data impacts the quality of decision-making.

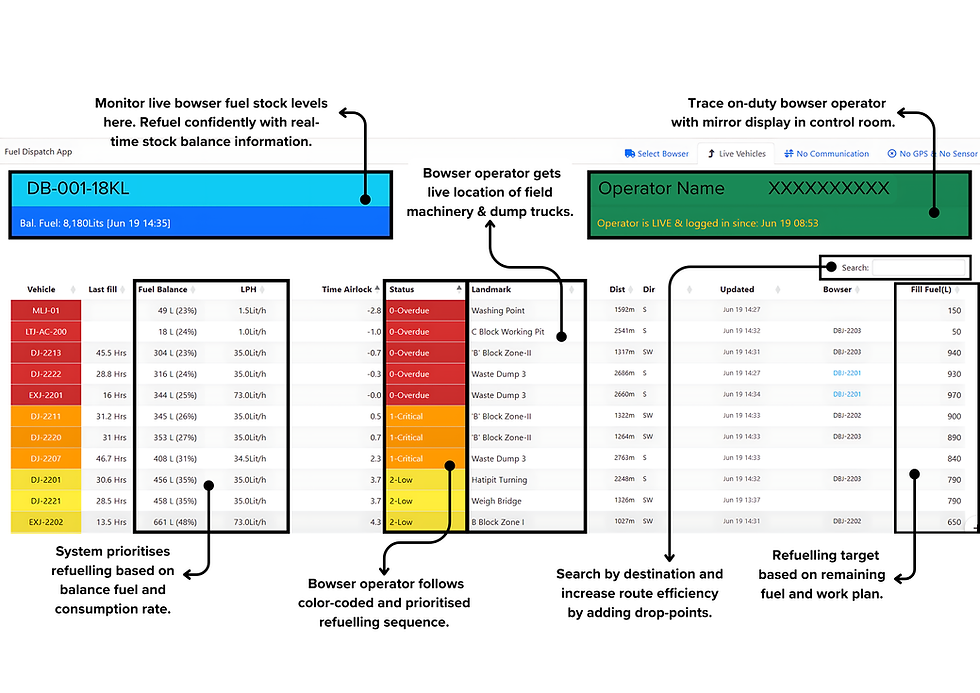

REFUEL DATAMASTER

This Daily Refueling Report is designed as a master record of all refueling transactions across every asset, everyday. Using date range settings users can see historical daily refueling trends for every asset; best of all, it captures live refueling data as it is getting generated. Fuel and Fleet managers can get fleet category aggregates and even contractor wise refueling aggregates. The report completely eliminates manual data capture and posting. The CSV download feature allows easy porting and analysis.

Another unique analytics is our enriched shift-wise run hour report, which provides detailed engine run hour data. By combining refueling data with run hour data, our LPH report enables site operations to analyze machine efficiency, allowing benchmarking of individual machine performance against fleet averages and OEM recommendations.

Mindshift’s instant data consolidation tool aggregates granular resource cost data, crucial for making informed resource allocation decisions that enhance machinery efficiency and reduce costs.

IMPACT

Previously, field data loggers rode fuel bowsers to manually capture refueling and HMR data, requiring at least four full-time employees (FTEs) annually, costing over US$ 10,000. Our application automates data capture, eliminating the need for these data loggers and freeing up resources for more value-added tasks.

Data entry operators used to manually post fuel and HMR data from registers or fuel slips into Excel sheets. Assuming 100 fuel slips per day at 3 minutes per slip, this task required one FTE annually, costing US$ 3,500. By automating this task, our application saves significant time and reduces costs by eliminating the need for manual data entry.

Managing Excel sheet aggregation and error correction was time-consuming. With a 5% error rate, approximately 1,825 errors out of 36,500 data posts could occur annually, each taking 5 minutes to identify and fix. Additionally, data aggregation, compilation, and reconciliation required one FTE annually, costing US$ 4,500. Our application drastically reduces these errors and automates data management, saving substantial costs and improving data accuracy.

CONCLUSION

Our data consolidation application significantly enhances operational efficiency and accuracy in refueling operations, resulting in substantial cost savings. By eliminating the need for manual loggers, data entry operators, and extensive management, the application ensures seamless, accurate, and cost-effective data handling. Experience the benefits of streamlined operations and reduced costs with our innovative application, keeping your refueling processes efficient and your bottom line healthy.

留言